Technical Proposal: Advanced Catalytic Recycling Process for Transforming Waste Engine Oil into High-Quality Diesel 1.0 Executive Summary This proposal outlines an advanced technological process for the efficient and sustainable conversion of Waste E...

Technical Proposal: Advanced Catalytic Recycling Process for Transforming Waste Engine Oil into High-Quality Diesel

This proposal outlines an advanced technological process for the efficient and sustainable conversion of Waste Engine Oil (WEO) into high-quality, specification-compliant diesel fuel. Traditional methods of WEO disposal, such as burning or illegal dumping, present significant environmental hazards. Our proprietary Integrated Catalytic Cracking and Hydrofinishing (ICCH) process represents a paradigm shift, offering a superior, economically viable, and environmentally responsible solution. This document focuses on the core technology and its distinct advantages over conventional pyrolysis or simple distillation methods.

Waste engine oil is a complex hydrocarbon mixture contaminated with metals, additives, oxidation products, water, and sediments. Simply re-refining it back to base oil is energy-intensive. Our technology is specifically engineered to break down the large hydrocarbon chains and molecules present in WEO into lighter, valuable diesel-range products while effectively removing contaminants.

Our ICCH process consists of three critical stages:

Process: Incoming WEO is first subjected to settling and centrifugation to remove solid particulates and free water. Subsequently, a vacuum dehydration system removes emulsified water and light fuels.

Advantage: This step prevents catalyst poisoning in subsequent stages and minimizes energy consumption during the main reaction phase.

Process: The pre-treated oil is fed into a precisely controlled pyrolysis reactor, heated in an oxygen-free environment to avoid combustion. The key differentiator is the introduction of a proprietary heterogeneous solid acid catalyst within the reactor.

Reaction: The catalyst selectively promotes the cracking of long-chain hydrocarbons (C20-C50) and the breakdown of complex aromatic structures and pollutants into middle-distillate range hydrocarbons (C10-C20), significantly increasing diesel yield.

Advantage (Catalytic Efficiency):

Lower Reaction Temperature: The catalyst lowers the required cracking temperature from >450°C (conventional thermal pyrolysis) to 320-380°C, drastically reducing energy consumption.

Higher Selectivity: The catalyst favors reactions that produce diesel-range products, maximizing yield and minimizing unwanted light gases (C1-C4) and heavy residues.

Cracking of Pollutants: The catalyst actively assists in breaking down sulfur and nitrogen compounds, making them easier to remove in the next stage.

Process: The vaporized products from the cracking reactor are immediately condensed into a liquid. This raw diesel is then upgraded in a fixed-bed hydrofinishing reactor under moderate pressure and temperature in the presence of hydrogen and a selective hydrotreating catalyst (e.g., Co-Mo/Al₂O₃).

Key Reactions:

Hydrodesulfurization (HDS): Removal of sulfur compounds.

Hydrodenitrogenation (HDN): Removal of nitrogen compounds.

Hydrodeoxygenation (HDO): Removal of oxygenated compounds.

Saturation: Conversion of olefins (causing instability) into stable paraffins.

Advantage (Product Quality): This step is critical for achieving a stable, clear, and specification-compliant fuel. It directly addresses the primary shortcomings of simple pyrolysis diesel, which is dark, unstable, and high in sulfur. The final product is fractionated to separate the high-quality diesel from a small fraction of naphtha (gasoline).

Our ICCH process demonstrates overwhelming advantages over existing technologies:

Reaction Mechanism | Pure Thermal Cracking atalytic Cracking

Temperature (>450°C) | **Moderate (320-380°C)

Energy Consumption Very High Low (up to 30% reduction)

Diesel Yield65-75% >85%

Product Quality Dark, unstable, high sulfur, requires extensive post-treatment Clear, stable, low sulfur, meets diesel specs

Environmental Impact High GHG emissions from energy use; hazardous waste | Lower carbon footprint; minimal waste

Operational Cost High (energy, post-treatment) | **Competitive and Optimized

Cetane Number: >45 (ensures good ignition quality)

Sulfur Content: <10 ppm (ultra-low sulfur diesel)

Stability: High resistance to oxidation and degradation during storage.

Color: Clear and bright, comparable to commercial diesel.

Waste Reduction: Diverts hazardous waste from landfills and prevents illegal dumping.

CirculaEconomy: reates valuable fuel from waste, reducing the need for virgin crude oil extraction.

Lower Emissions: The process itself is energy-efficient, and the final low-sulfur fuel burns cleaner, reducing SOx and NOx emissions from end-use.

High Yield: Maximizing diesel output directly improves project economics and ROI.

Reduced Utility Costs: Lower operating temperatures translate directly to lower fuel or energy input costs.

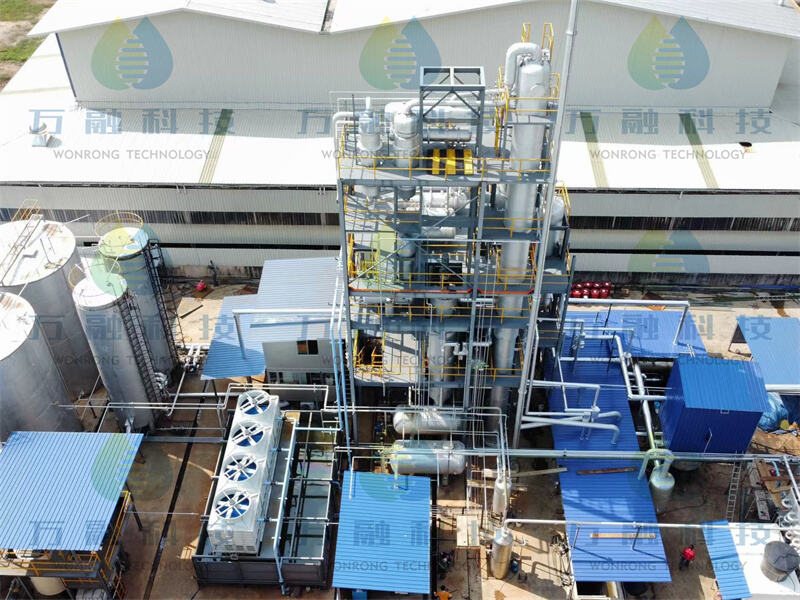

Modular Design: The plant can be designed in modular units, allowing for scalability from small-scale (5 tons/day) to large-scale (50+ tons/day) operations to suit market needs.

The proposed Integrated Catalytic Cracking and Hydrofinishing (ICCH) technology is not merely a recycling process but a advanced fuel manufacturing platform. It successfully transforms the environmental liability of waste engine oil into a high-value, specification-grade diesel fuel. The core technological advantages—catalytic efficiency, significantly lower energy demand, superior product quality, and robust environmental benefits—position this solution as the leading choice for sustainable and profitable waste oil management.

We are prepared to provide a detailed feasibility study and commercial offer tailored to your specific requirements.